Superior Valve Products

Superior Valve Products

316 Equity Blvd.

Houma, LA 70361

ph: 985-879-3888

fax: 985-879-3846

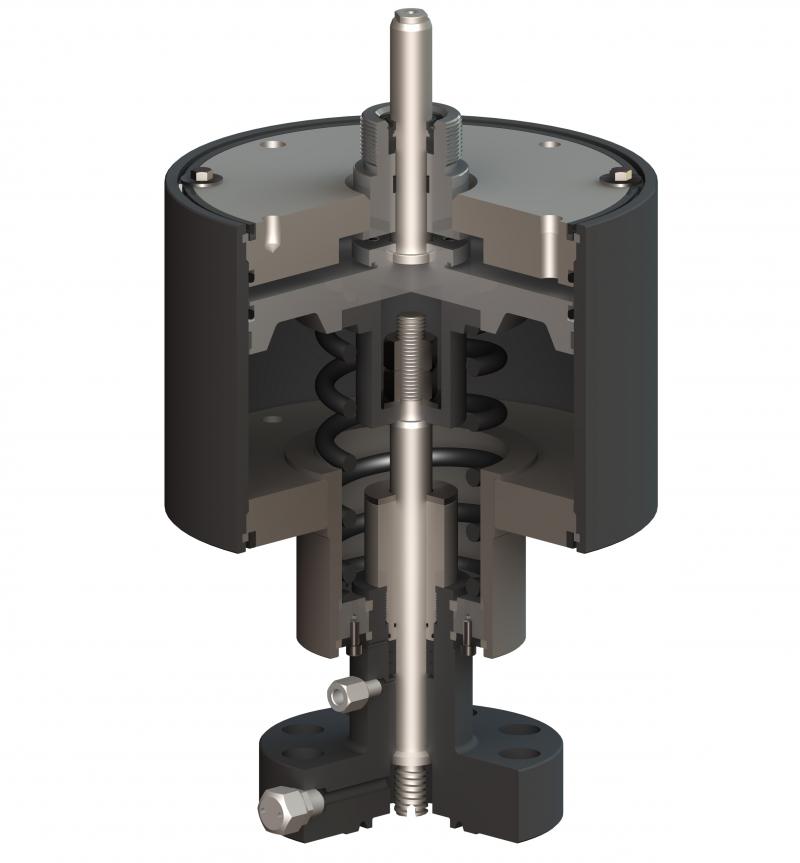

Model PX Piston Actuators

Introduction:

Omni Model PX pneumatic piston actuators are designed to operate surface safety or shutdown valves on oil & gas wellhead, transmission, storage, manifold or other applications where fail-safe capability is required. Model PX actuators can be used for land or off shore installations and are engineered to provide reliable service in a variety of operating conditions. Omni can provide Model PX actuators already mounted on valves and ready to deploy, or as actuated bonnet assemblies ready to mount on valves from other manufacturers. Additionally, Omni offers a full range of accessories including standard & fusible manual overrides, position indicators, and standard & fusible lock open devices.

Features:

Flexibility

Model PX actuators can be adapted to operate valves from any manufacturer (interface information is required) and can be delivered with alternate materials of construction if required by field conditions.

Over-Pressure Protection

Model PX actuator come equipped with pressure relief devices to protect personnel and guard against damage to the actuator in case of an over pressure condition. The pressure relief device is easily inspected and is field-replaceable.

Orientation, Rotation & Ease of Piping

Model PX actuators have pressure inlet and outlet ports located at convenient locations on the upper housing assembly and can be rotated to facilitate proper piping orientation based on field conditions. Once proper orientation has been achieved, the actuator’s lower bonnet retaining ring can be locked into place to prevent accidental rotation of the actuator while in service.

Backseat & Packing Integrity

Model PX actuators incorporate bonnet assemblies that have an integrated metal-to-metal backseat. A bonnet fitting can also be used to relieve any pressure that might be trapped between the backseat and stem packing after the backseat operation. A tattletale weep port is located above the packing to provide visual confirmation of stem seal integrity during operation. All Model PX ports can be used to pipe fugitive emissions to a containment vessel, if required.

Corrosion Protection

Model PX actuator housings are internally and externally coated to prevent corrosion due to environmental conditions. All internal components are either stainless steel or are coated to prevent corrosion due to any contamination that might be present in the control pressure source.

Maintenance

Model PX actuators are designed for ease of maintenance. All nonmetallic seals and other par ts are easily replaceable.

Available Sizes:

MODEL SIZE STROKE

PX-09 9" 2-1/16" bore

PX-13 13" 3-1/8" bore

PX-15 15" 4-1/16" bore

PX-18 18" 7-1/16" bore

PX-20 20" 7-1/16" bore

Copyright 2011 Superior Valve Services. All rights reserved.

213 Gemini Ct.

Houma , LA 70360

ph: 985-879-3888

fax: 985-879-3846